Quick Link

PATCH COLD

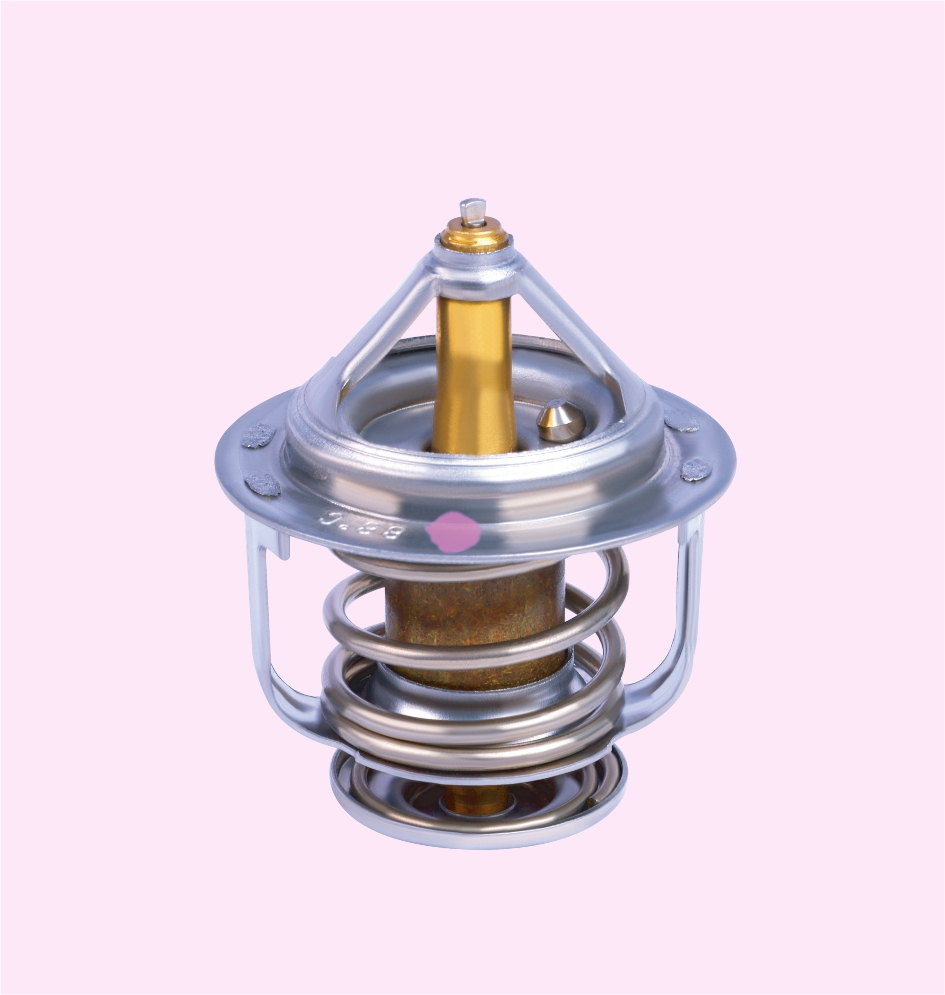

THERMOSTAT

AUTOMATIC TRANSMISSION FLUID

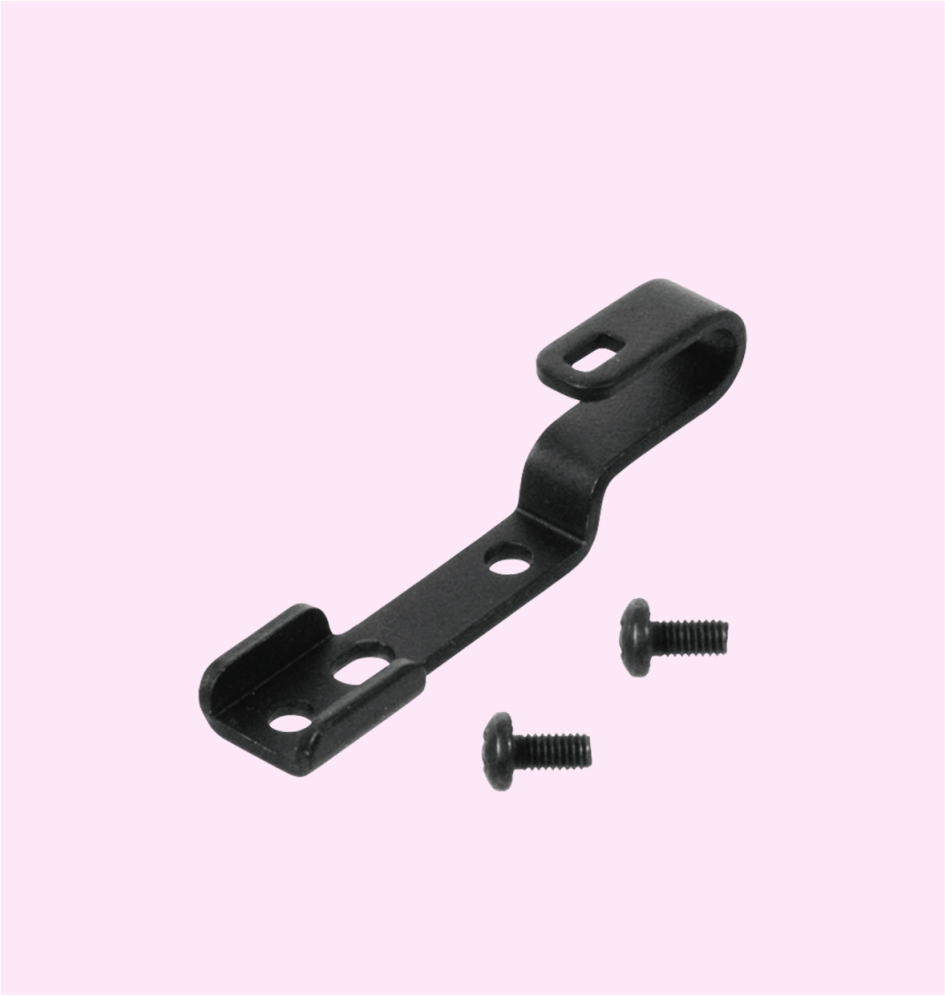

BATTERY RETAINING CLAMP

COOLANT

BRAKE FLUID

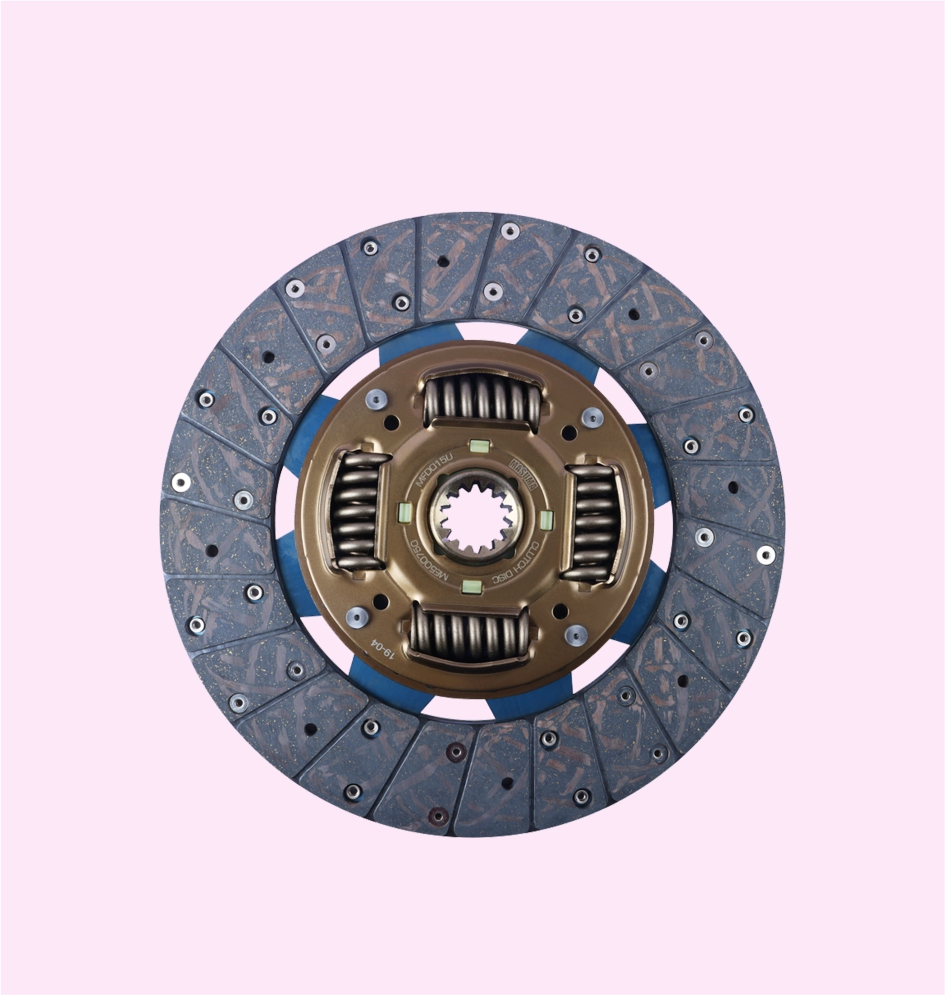

CLUTCH DISC

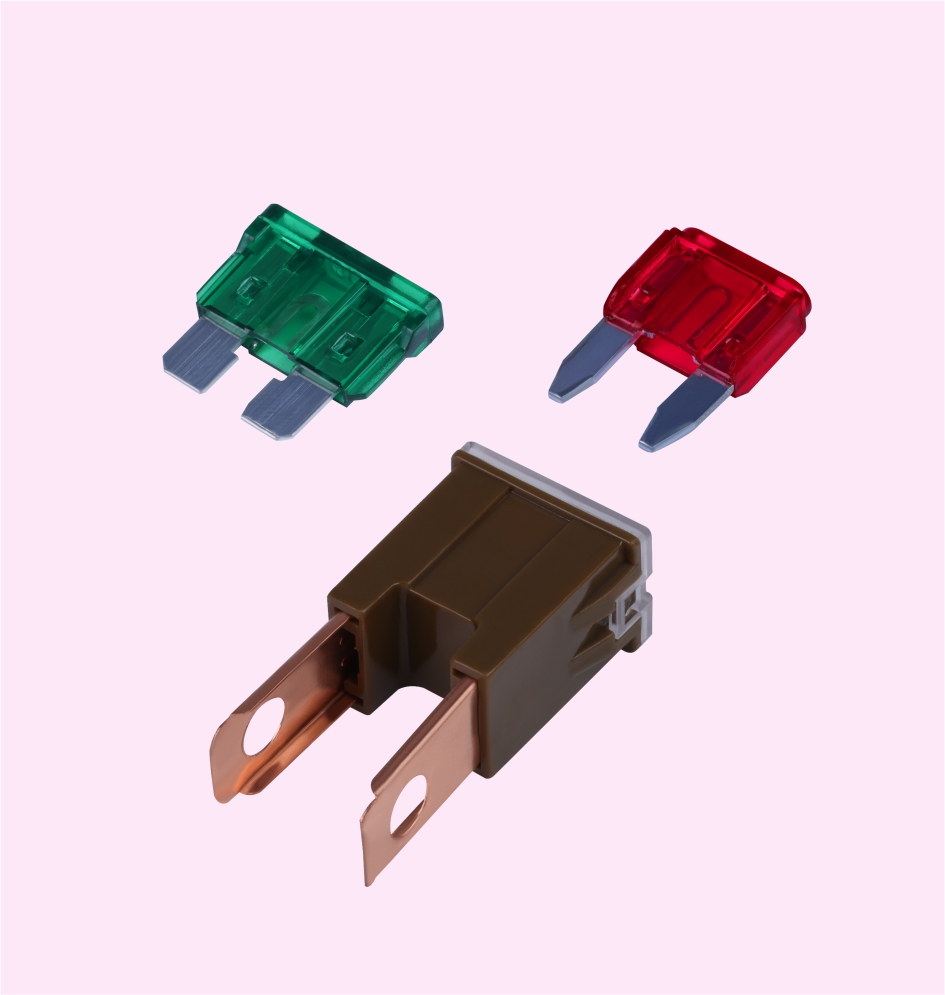

AUTOMOTIVE FUSE

REFRIGERANT

BATTERY INTAKE FILTER

OXYGEN SENSOR

IGNITION COILS

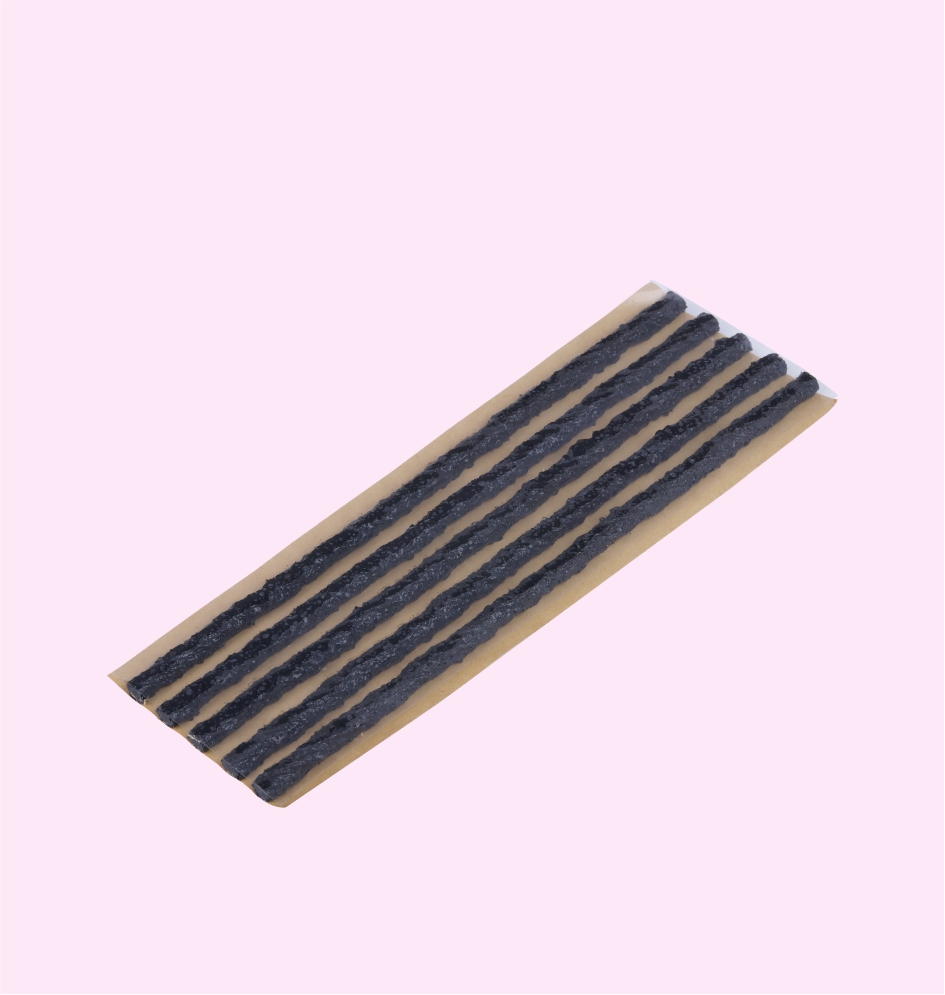

TIRE PLUG KIT

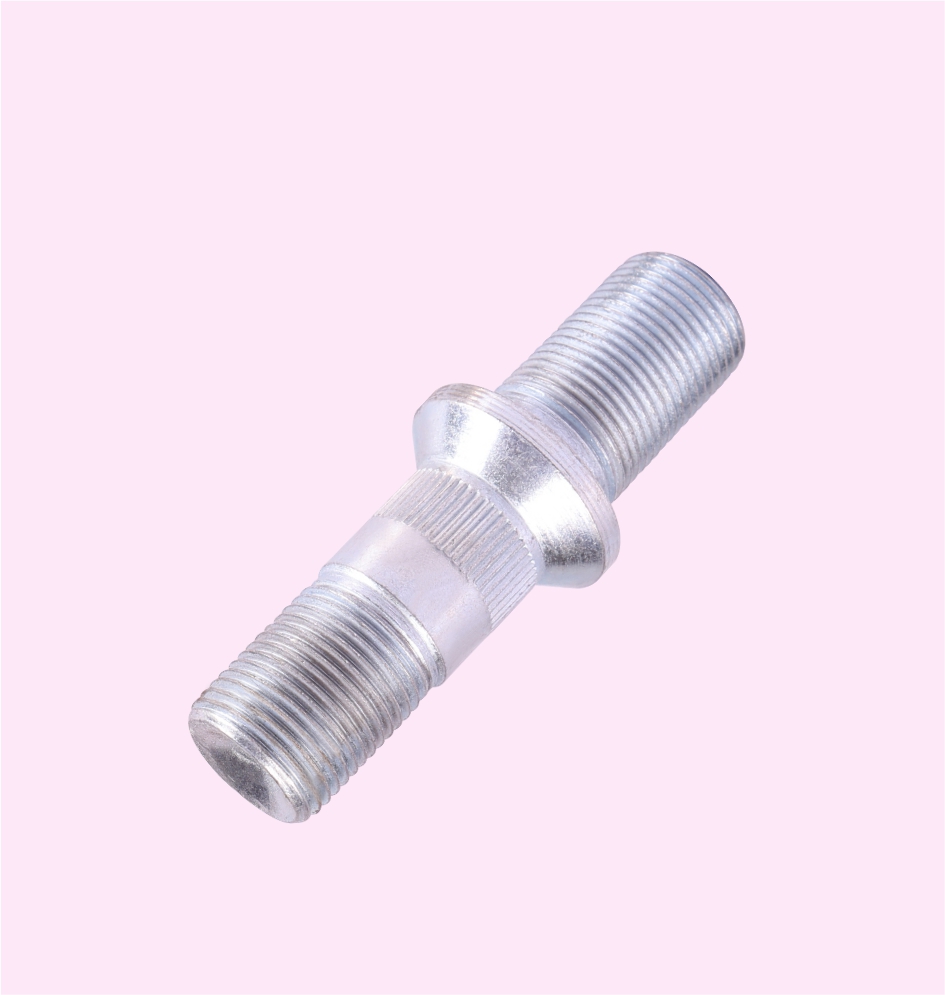

HUB BOLT

AIR FLOW SENSOR

RTV SILICONE

HOSE CLAMP

GREASE FITTING

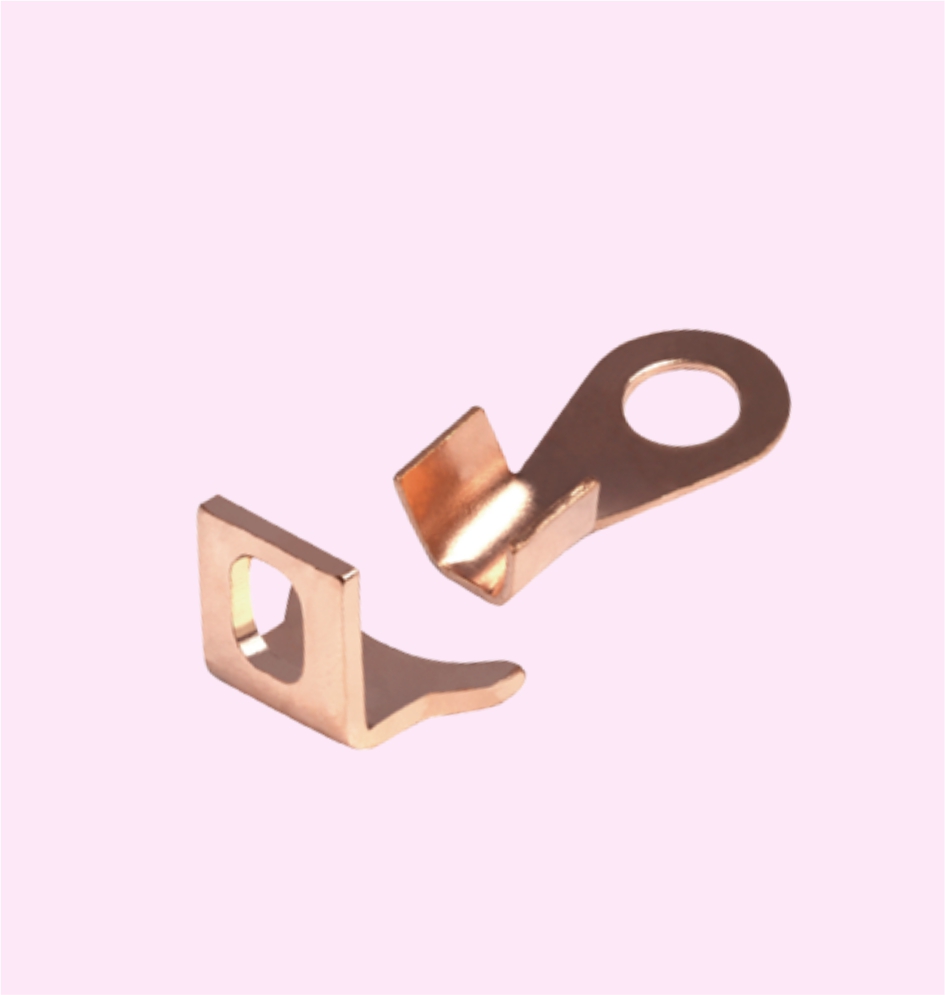

STARTER CONTACTS

SPARK PLUGS

GLOW PLUG

VULCANIZING CEMENT

RADIATOR

WHEEL CYLINDER

BALL JOINT

SHOCK ABSORBERS

ENGINE MOUNTING

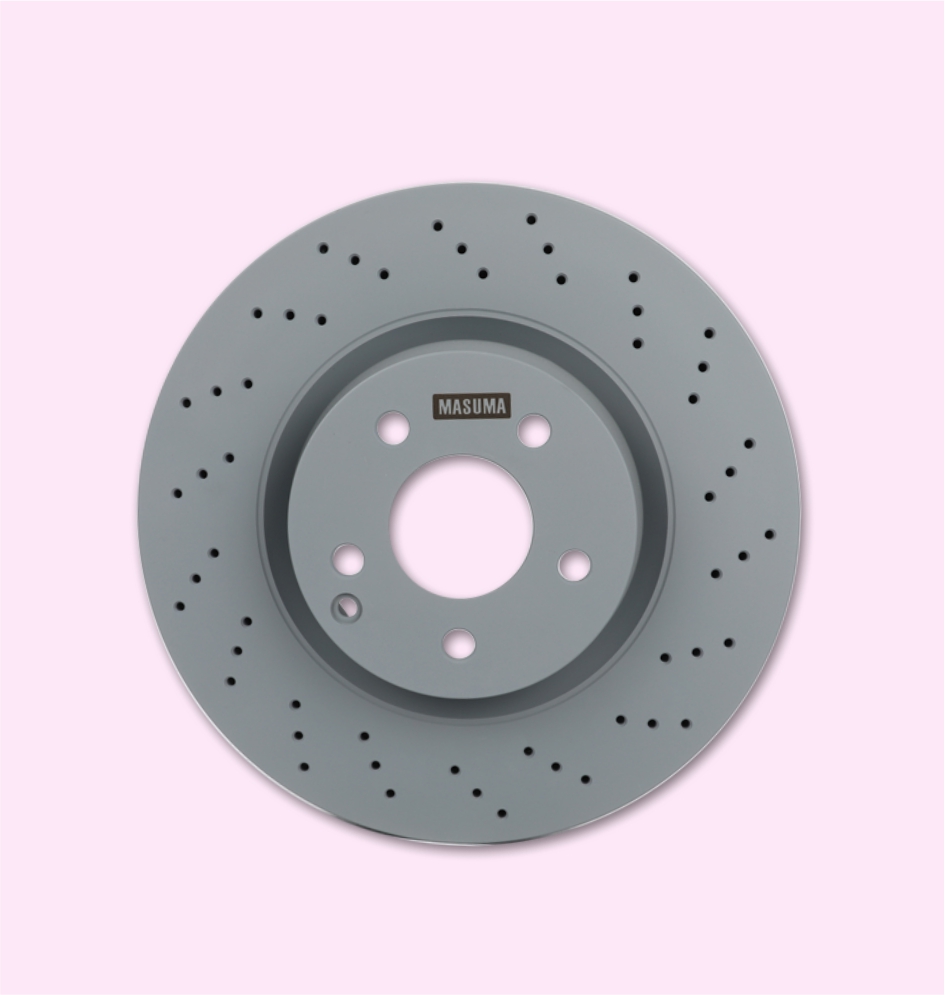

BRAKE DISC

BRAKE & PARTS CLEANER

CONTROL ROD

TAPPING SCREW

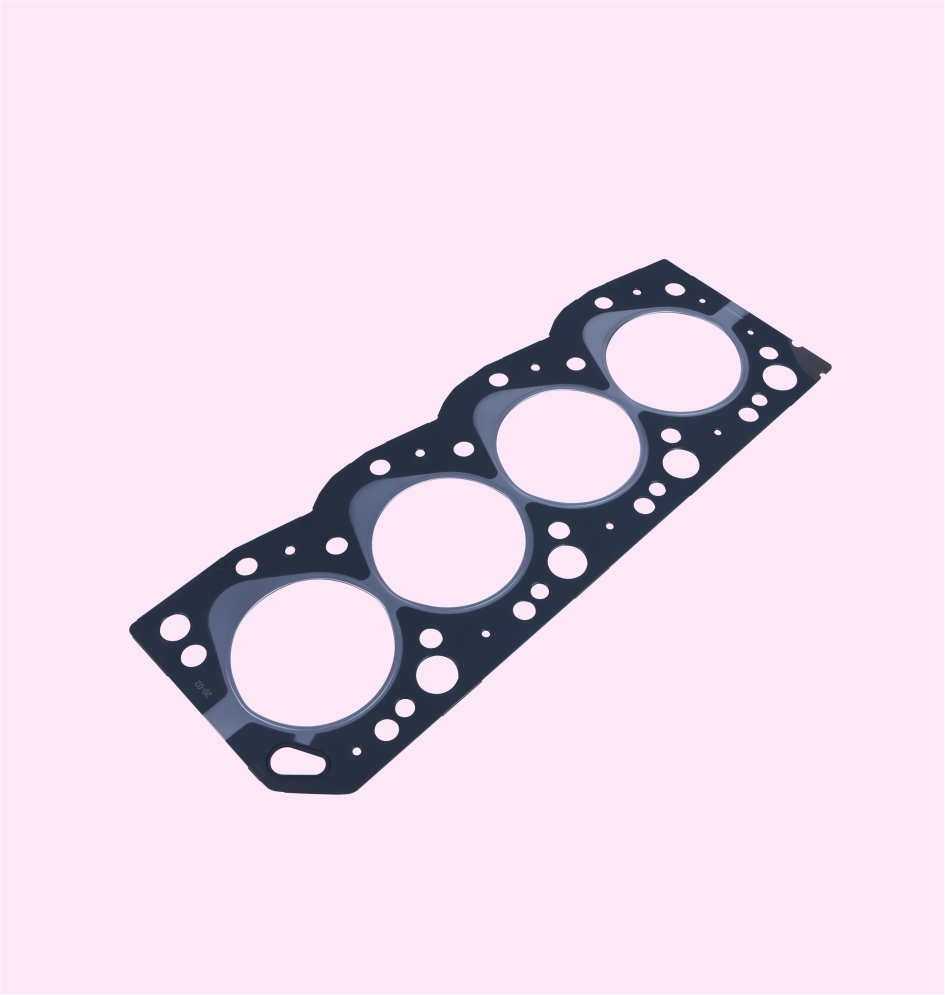

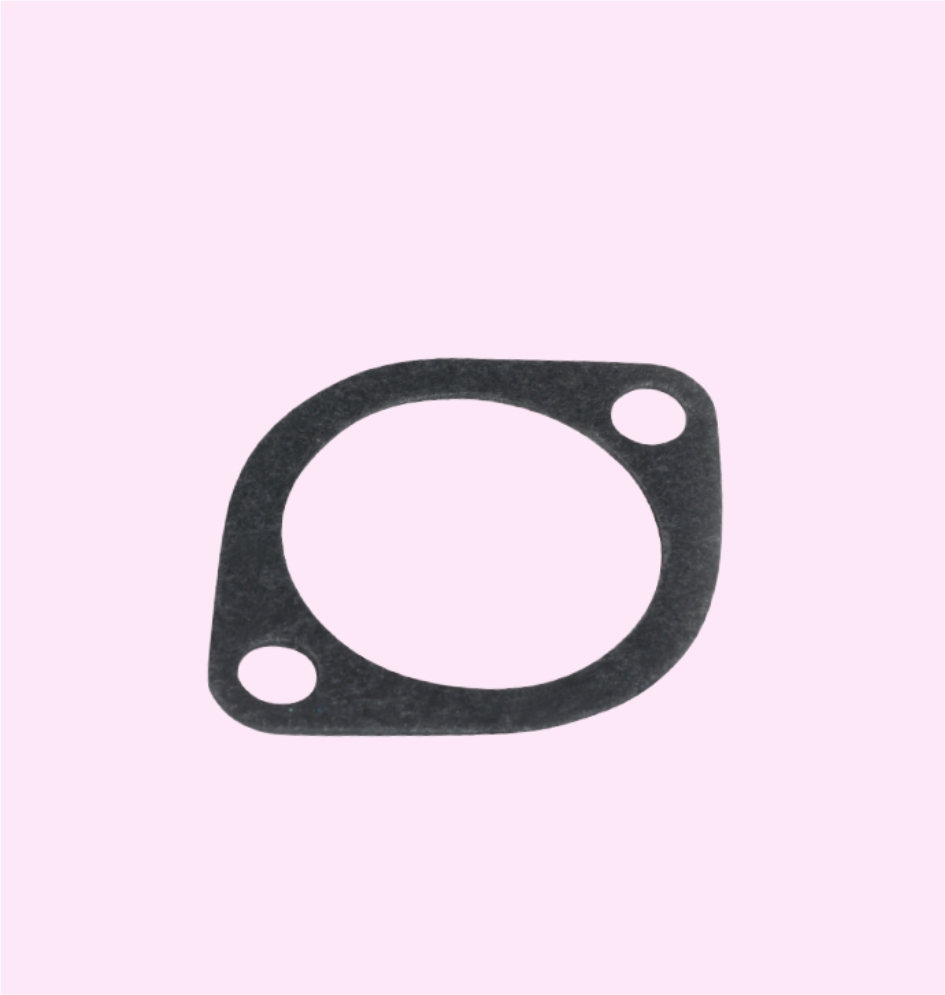

ENGINE GASKET

MOTOR OIL

FUEL PUMP STRAINER

SPARK PLUG CABLE SET

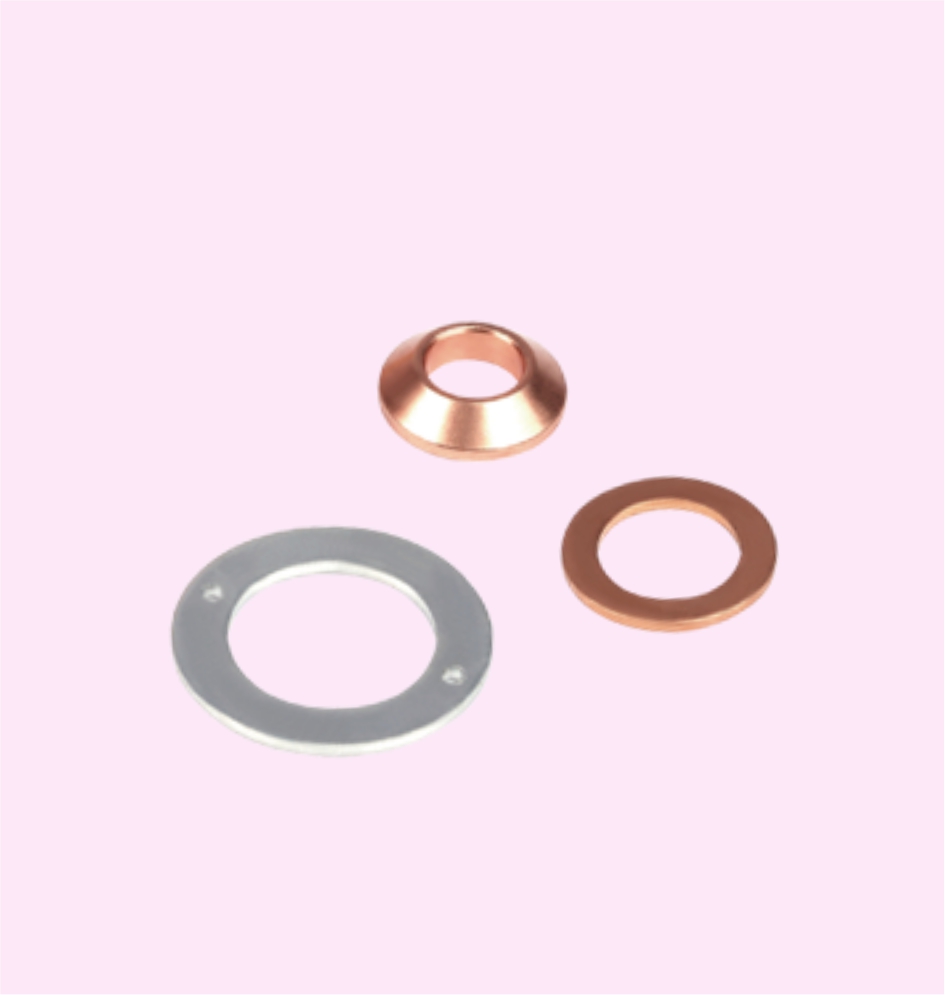

INJECTOR WASHERS

UNIVERSAL JOINT

WHEEL NUT

STEERING BOOT

OUTER C.V. JOINT

DISC BRAKE SEAL KIT

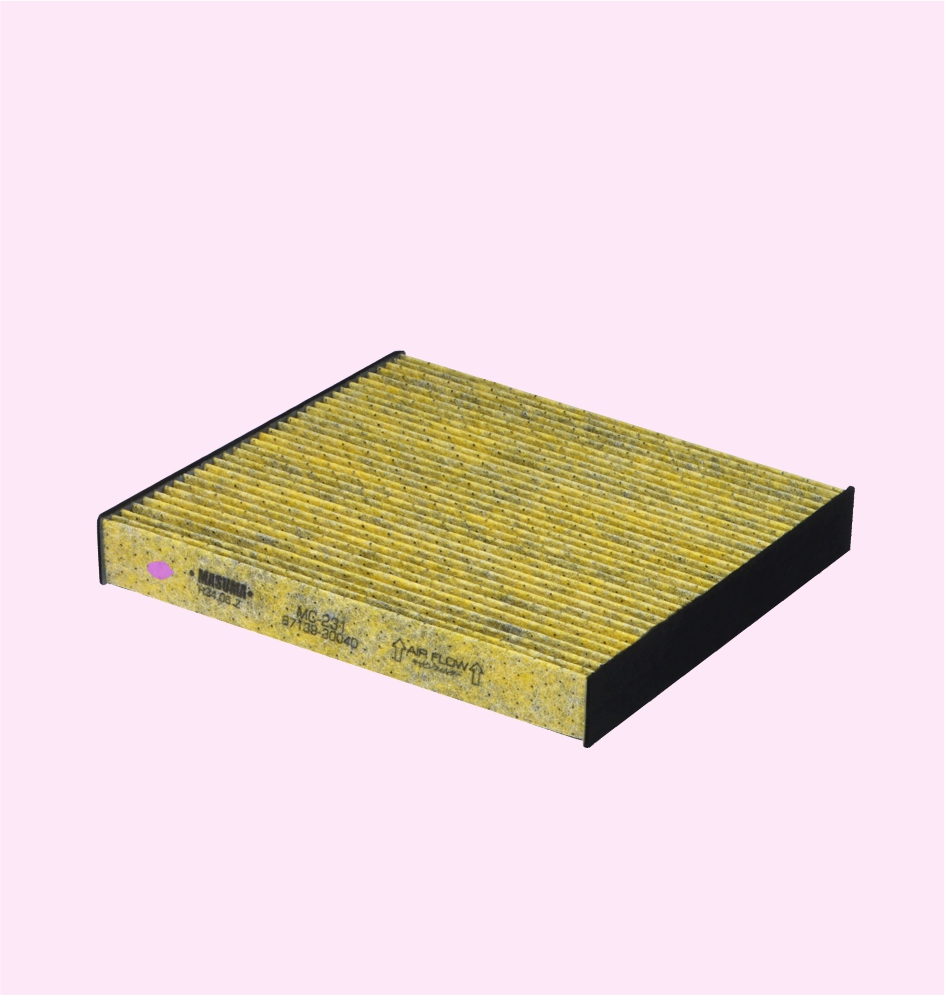

CABIN FILTER

STABILIZER BUSH

DRIVE SHAFT BOOT KIT

BRAKE HOSE

BRASS BUSHES (FOR STEERING KNUCKLE)

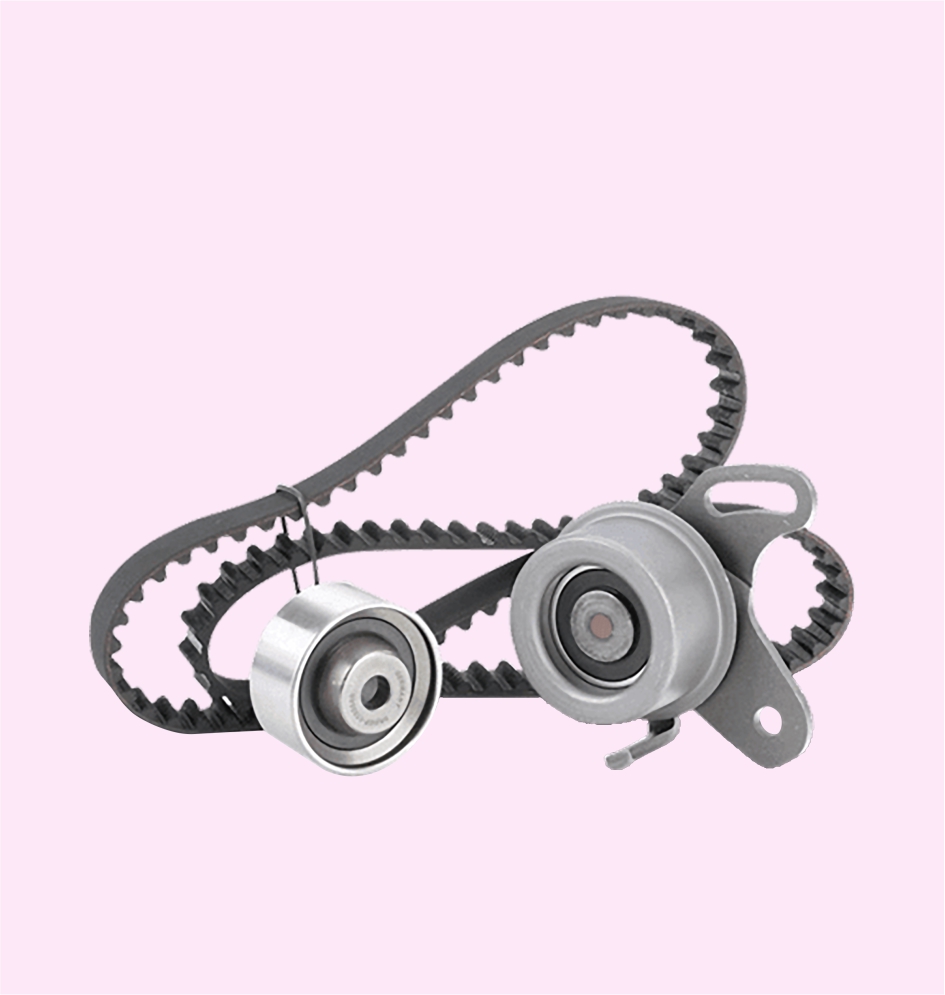

BELT TENSIONER IDLER

TIMING CHAIN KIT

BRAKE SHOE

THERMOSTAT GASKET

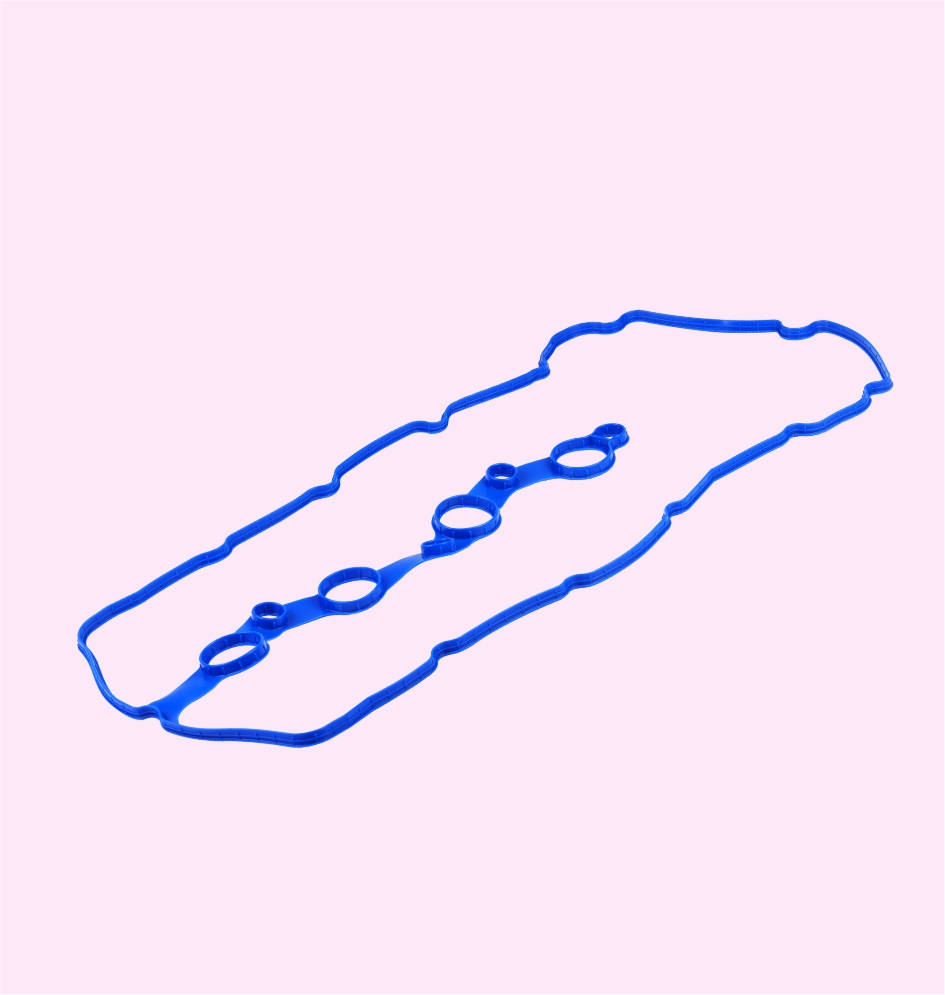

VALVE COVER GASKET

AUTOMOTIVE RUBBER PARTS

WHEEL HUB UNIT

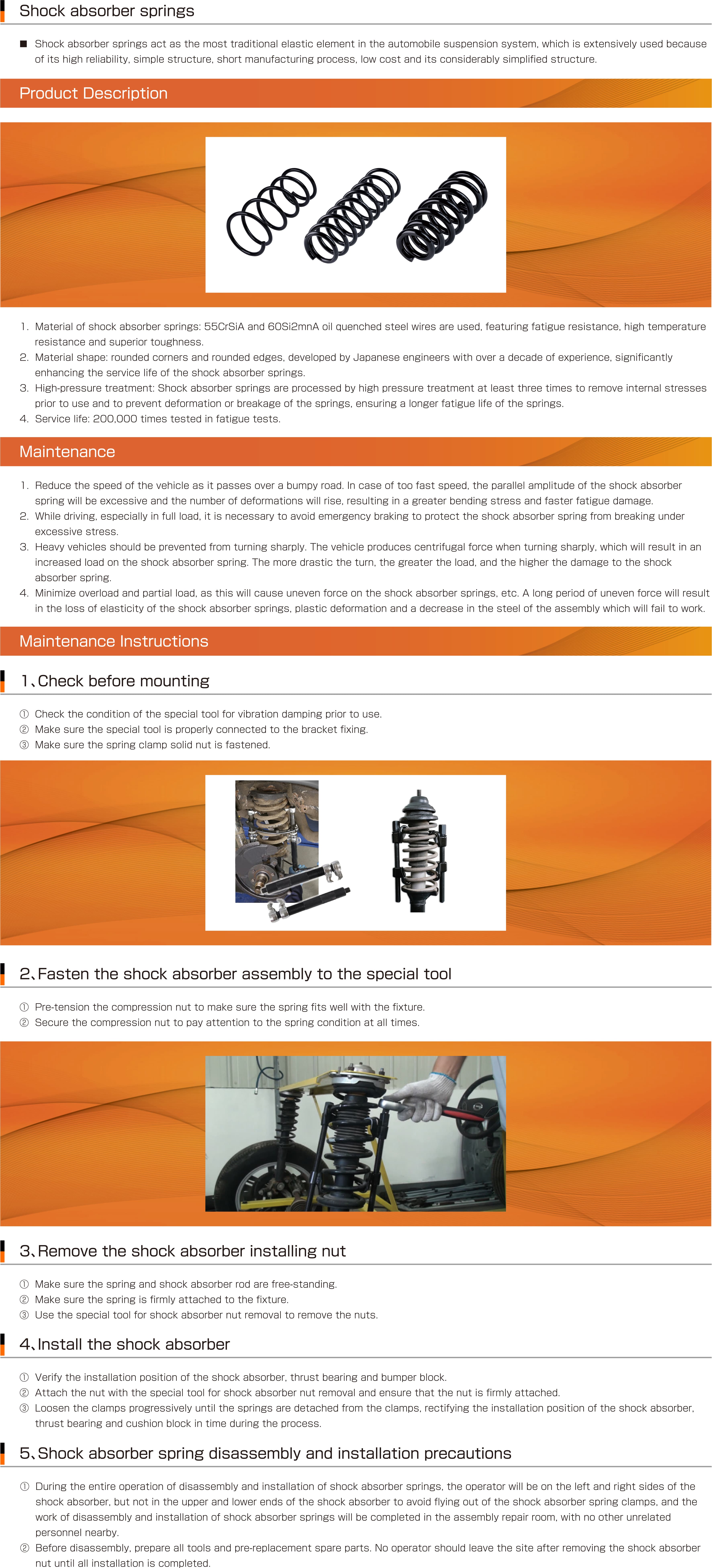

COIL SPRING

DISC BRAKE PADS

CLUTCH RELEASE BEARING

CLUTCH COVER

AIR CONDITIONING COMPRESSOR

FUEL PUMP ASSEMBLY

BEARING SHOCK MOUNTING

OIL SEAL

CONDENSER

STEERING RACK

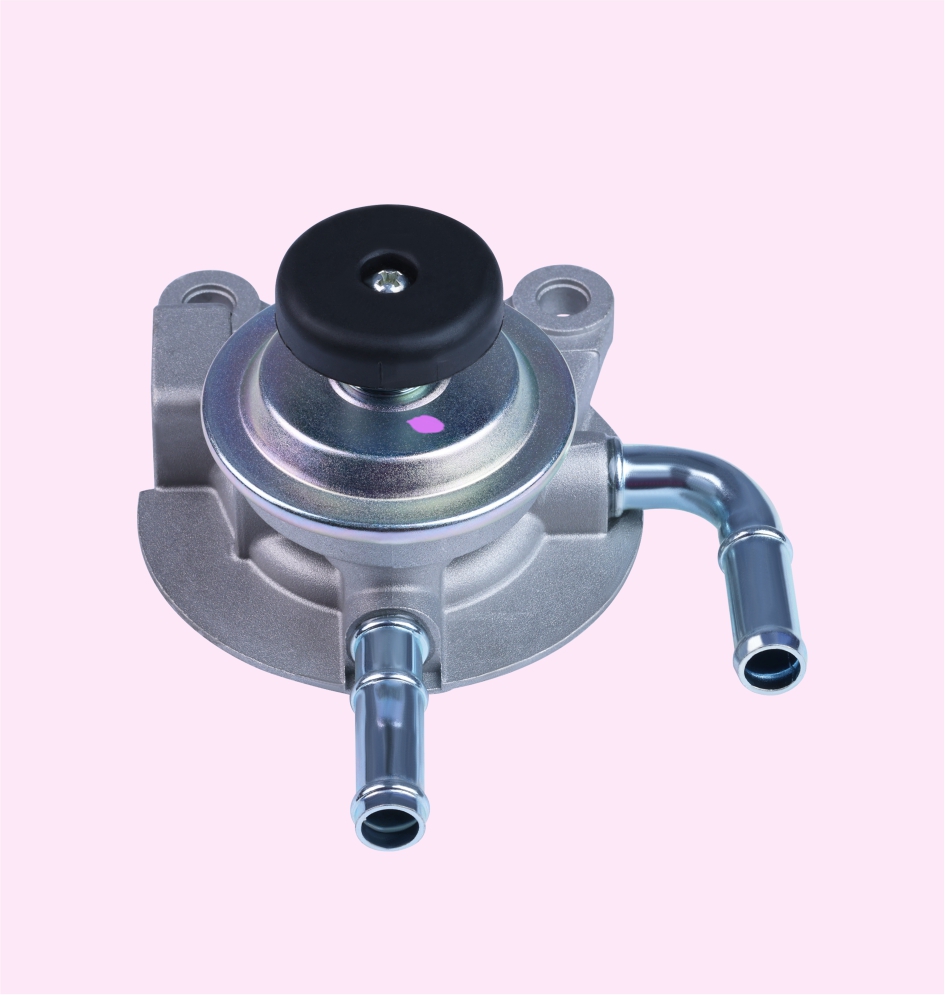

FUEL PUMP

CAP ASSY FUEL FILTER

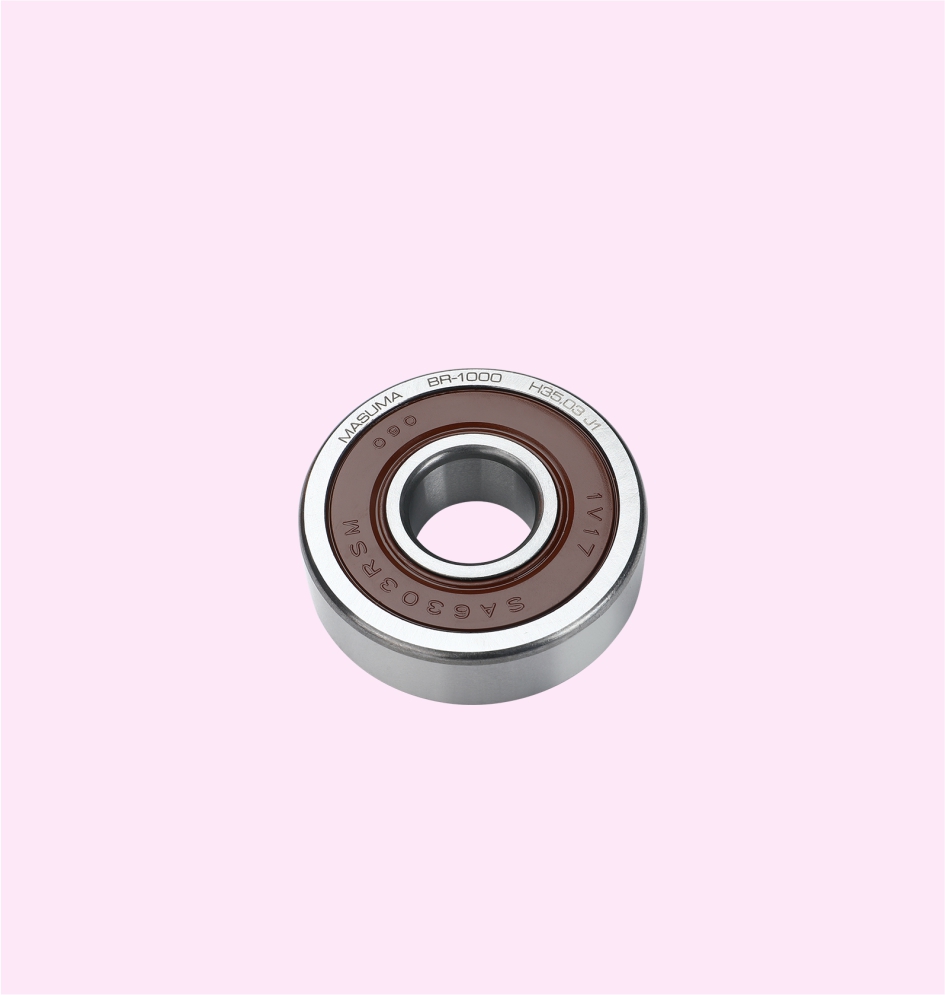

WHEEL HUB BEARING

CV JOINT BOOT CLAMP KIT

HYDRAULIC FILTER

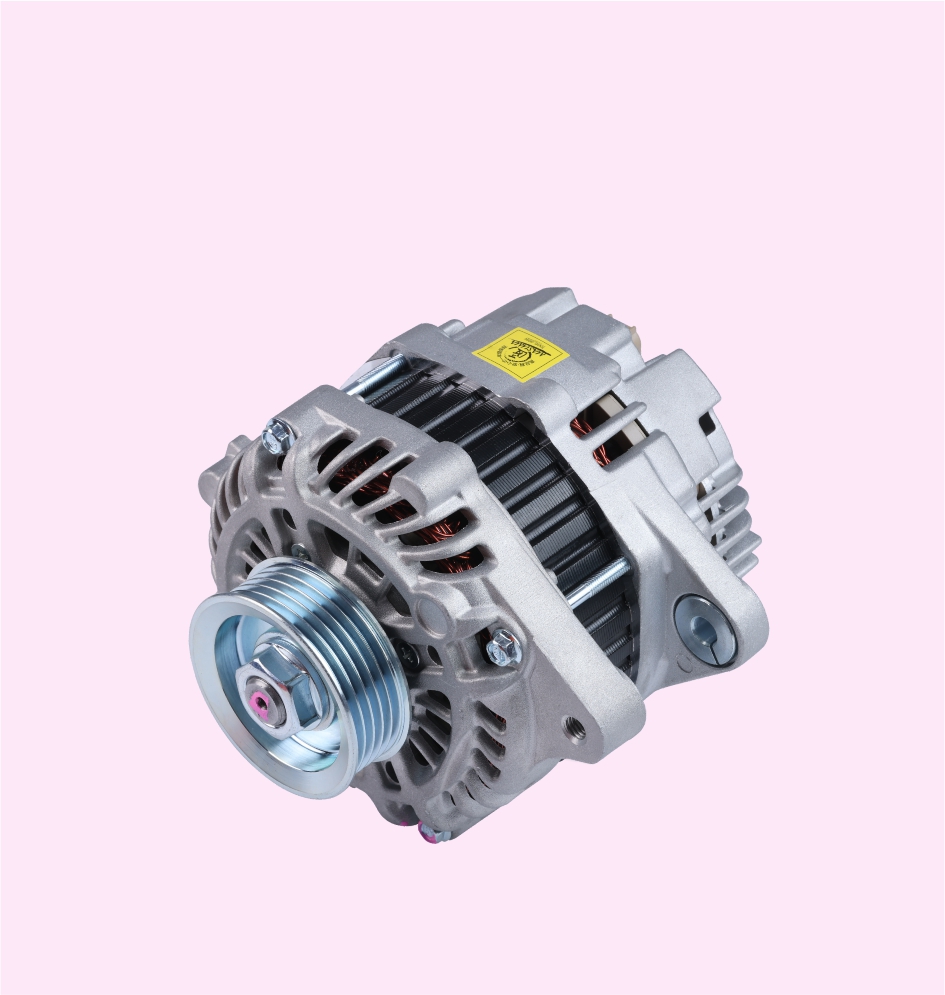

ALTERNATOR

STARTER MOTOR

WATER PUMP/ELECTRONIC WATER PUMP

SENSOR FUEL FILTER

POWER STEERING PUMP

TIMING BELT

STRUT MOUNT

BRAKE PAD WEAR SENSOR

AIR FILTER

OIL FILTER

FUEL FILTER

CONTROL ARM

RACK END

TIE ROD END

STABILIZER LINK

GAS SPRING

BALL JOINT DUST COVER

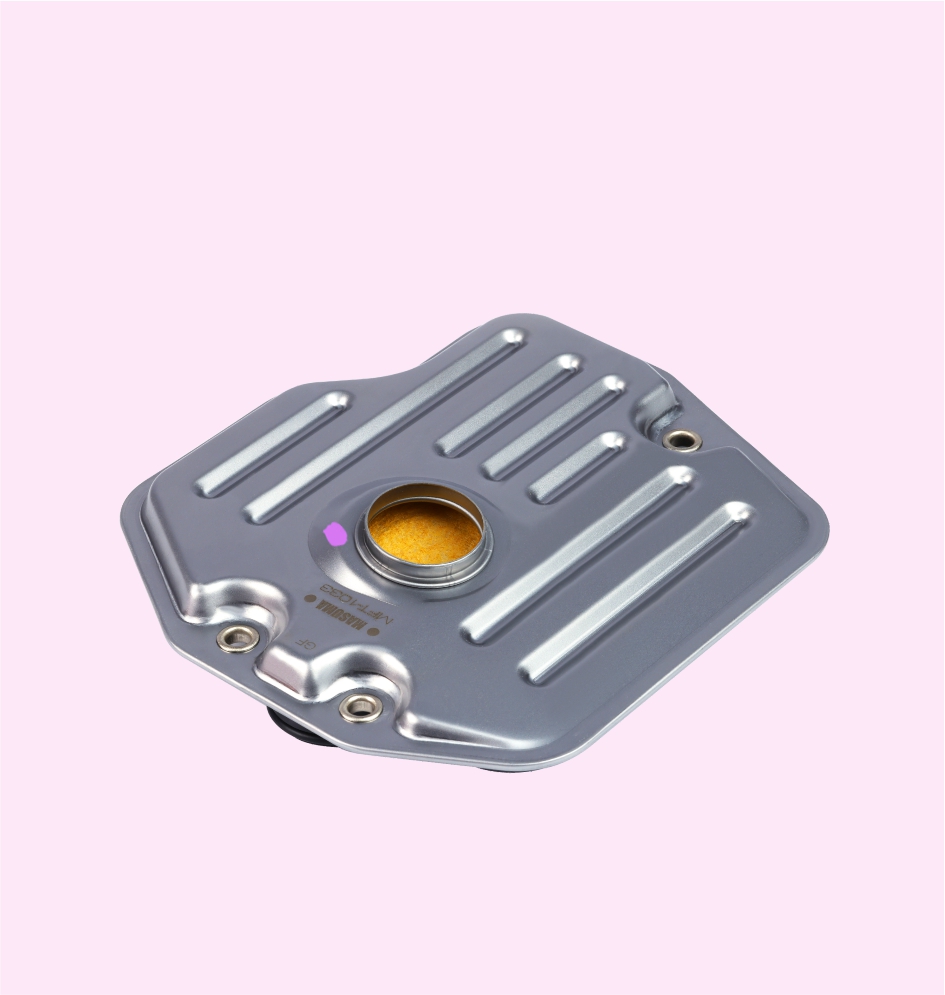

TRANSMISSION FILTER

AUTOMOTIVE CLIPS & FASTENERS

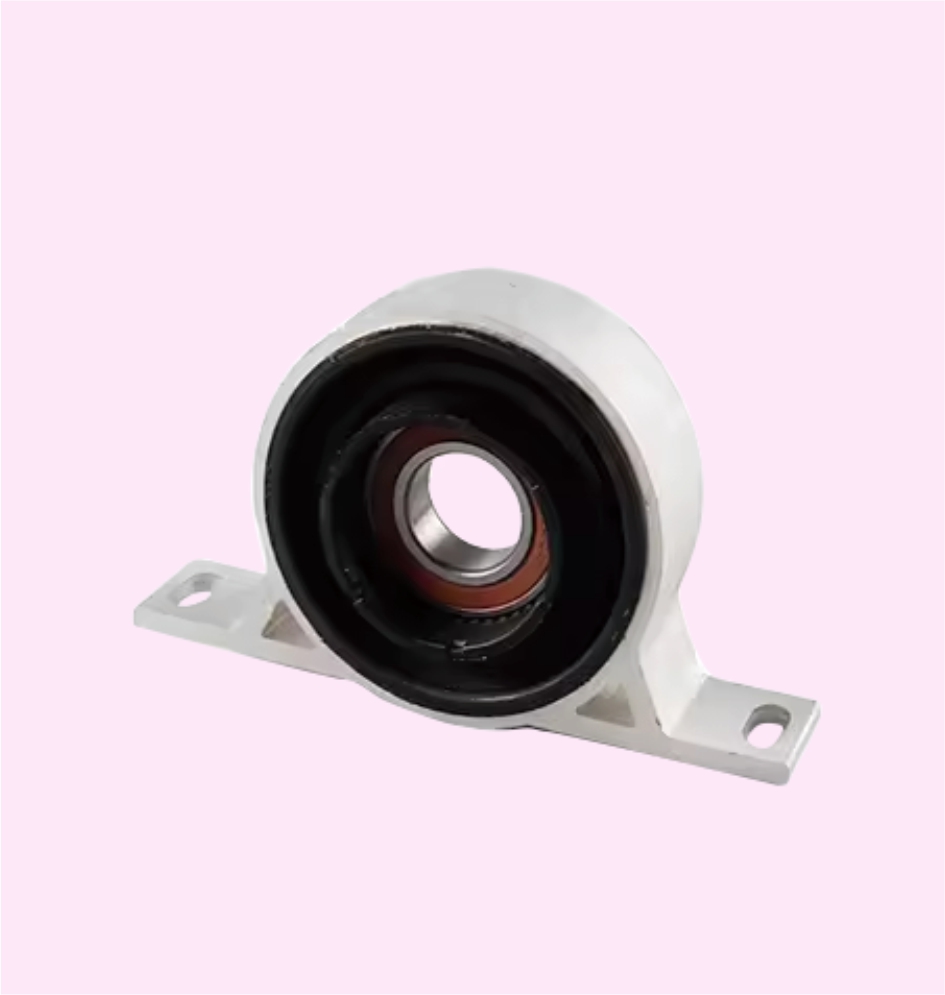

CENTER SUPPORT BEARINGS

CARBURETOR CLEANER

FOAM CLEANER

SILICONE SPRAY

PITCH CLEANER

MOTOR FLUSH

TRIM & PLASTIC RESTORER

C .V. JOINT GREASE

BRAKE MASTER CYLINDER

DRIVE SHAFT

MF BATTERY

FUEL INJECTOR

TURBOCHARGER

FUEL TANK CAP

CAM PHASER

V-BELT

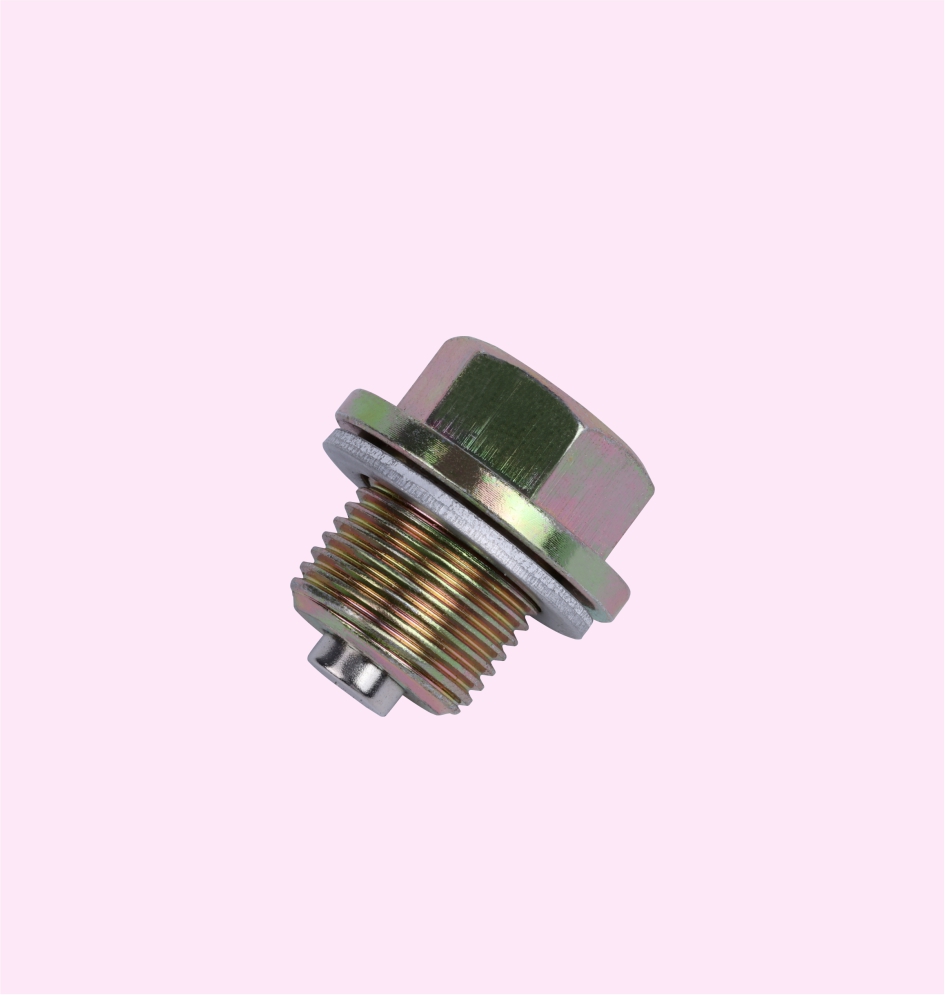

DRAIN BOLT

V-RIBBED BELT

TIRE REPAIR PLUG

MULTI-PURPOSE LUBRICANT

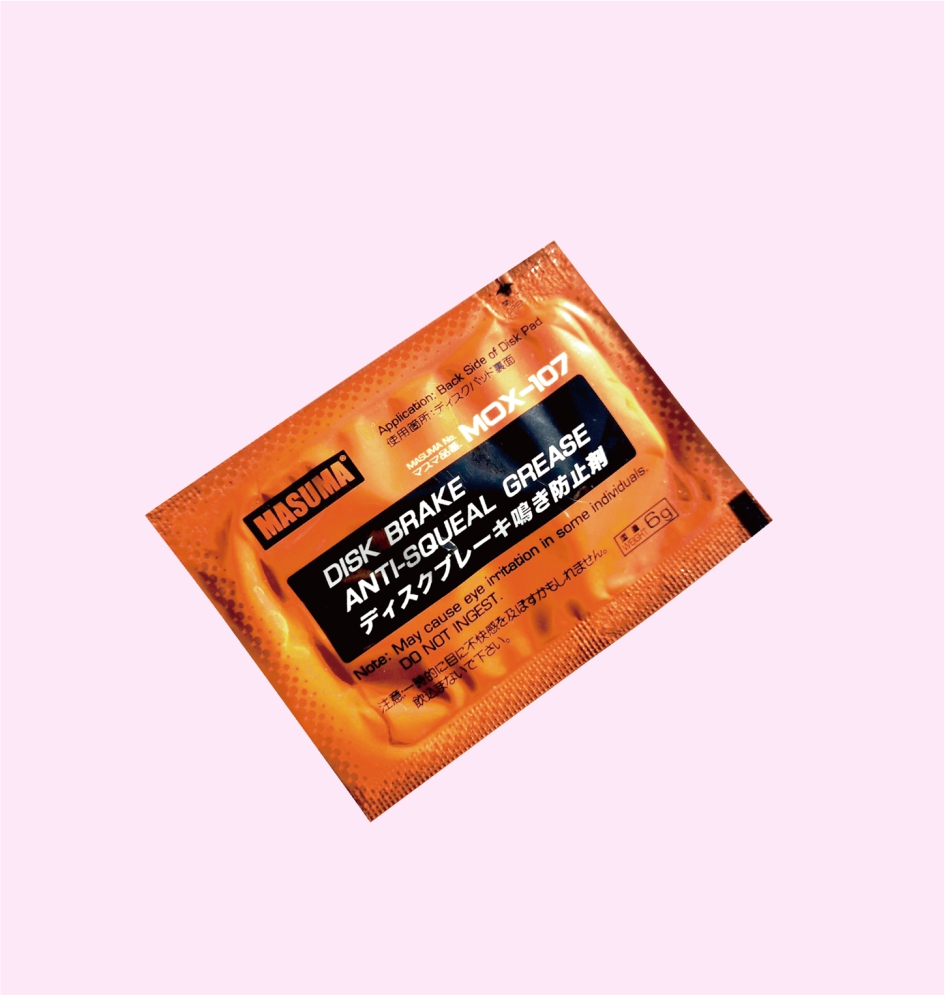

DISK BRAKE ANTI-SQUEAL GREASE

BRAKE CLEANER KIT

PROPELLER SHAFT

RADIATOR DRAIN COCK

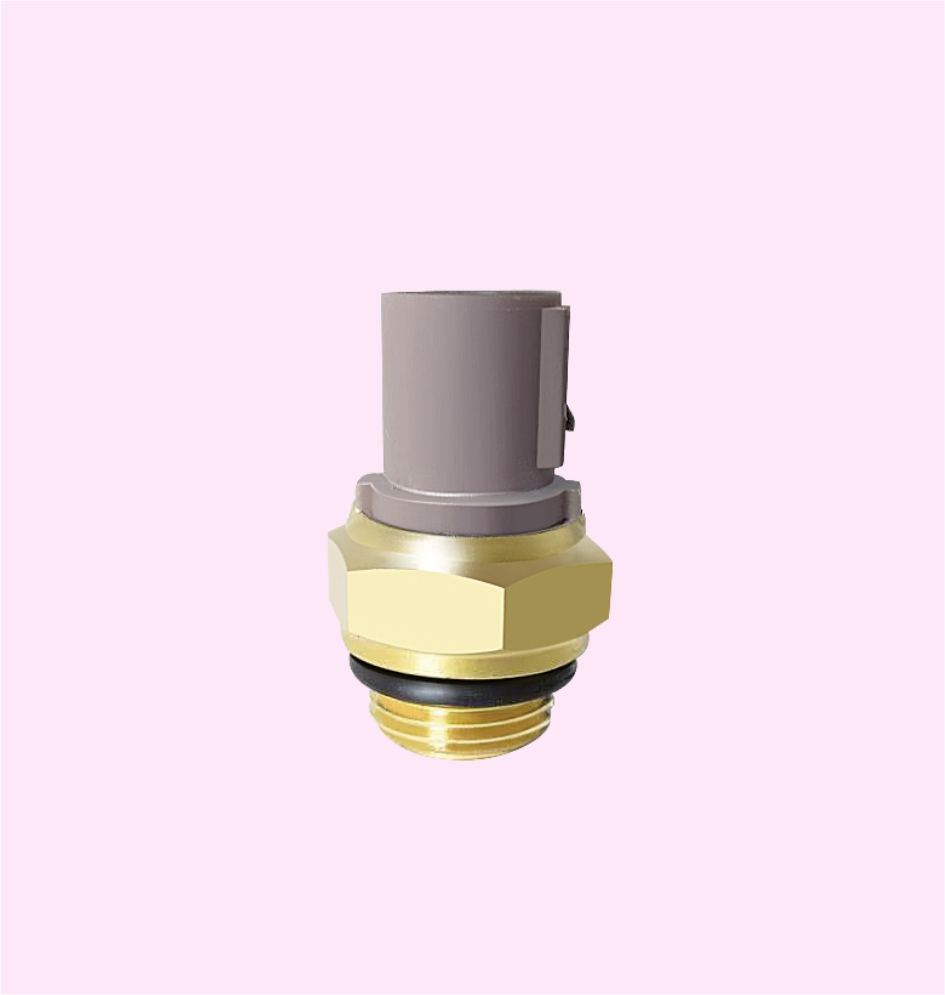

THERMO SWITCH

GRAPHITE GASKET

WIPER RUBBER

HORN

RADIATOR CAP

BRAKE CYLINDER GREASE

WIPER BLADE ADAPTER

AUTO EXHAUST FLEXIBLE PIPE

SPHERICAL JOINTS PIPE

WIPER BLADE DISPLAY STAND

DISPLAY STAND

OIL QUALITY COMPARATOR

SPARK PLUG TESTER

OIL FILTER CUTTER

POLO SHIRT

T-SHIRT (ORANGE)

T-SHIRT (BLACK)

JACKET

OVERALLS

COVERALLS

REFLECTIVE VEST

BASEBALL CAP(BLACK)

BASEBALL CAP (ORANGE)

13G POLYESTER LATEX COATD GLOVES

UMBRELLA

BACKPACK

MOUSE PAD

THROW PILLOW

COMPANY FLAG

WATER FILLED BANNER FLAG

PLASTIC BAG

FOLDER (SINGLE LAYER)

FOLDERS (MULTIPLE LAYERS)

ZIPPER FILE HOLDER

ELECTRIONIC QUARTZ CLOCK

WHEEL HUB WATCH

ASHTRAY

VACUUM THERMOS FLASK(BLUE)

SQUARE LIGHT BOX SIGNAGE

AIR FRESHENER

ADVERTISING STICKERS

BELT MEASURING GAUGE

MAGNETIC PARTS TRAY

BUSHING REMOVAL & INSTALLATION TOOL KIT

BRAKE WHEEL CYLINDER REPLACEMENT TOOL

MECHANICS CREEPER

CREEPER SEAT

DISPOSABLE CAR SEAT COVER

DISPOSABLE STEERING WHEEL COVER

DISPOSABLE FLOOR MATS

BRAKE FLUID FLUSH & EXCHANGE MACHINE

COOLANT FLUSH & EXCHANGE MACHINE

TRANSMISSION FLUID FLUSH & EXCHANGE MACHINE

TRANSMISSION FLUID NOZZLE

A/C CHARGING HOSE

BRAKE DISC LATHE

BUSHING REMOVAL & INSTALLATION TOOL

MAGNETIC FENDER COVER WORK MAT

AUTO TRIM REMOVAL TOOL

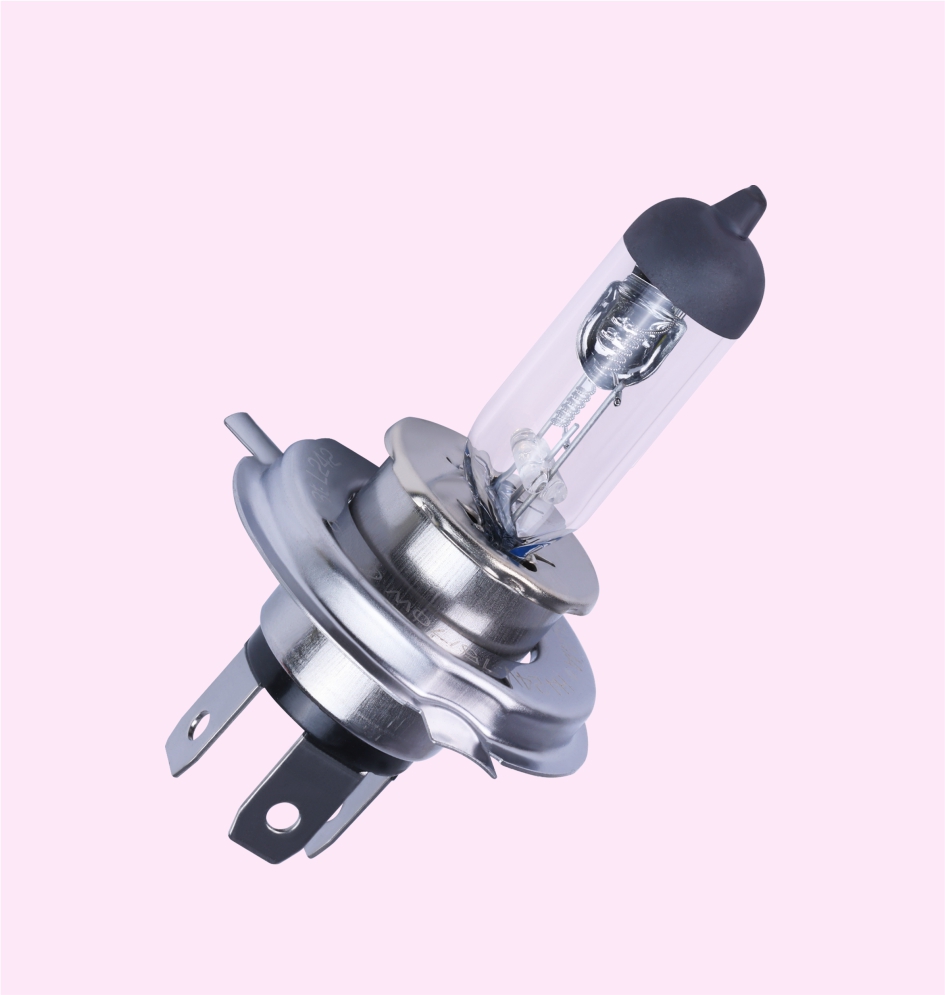

HALOGEN BULB

LED BULBS

XENON HID BULB

C.V. JOINT NUT

BRACKET BOLT

ECCENTRIC BOLT

TIMING BELT KIT

SHOCK ABSORBER DUST COVER

WIPER BLADE(NANO GRAPHITE)

WIPER BLADE

BEAM WIPER BLADE

REAR WIPER

REAR SNOW BLADE

TRUCK WIPER

SNOW BLADE

SNOW BLADE (NANO GRAPHITE)

FLAT WIPER BLADE

REAR WIPER (SILICONE UNVERSAL)

ALTERNATOR BEARING

Steering Shaft

AIR SPRINGS

LIMITED SLIP DIFFERENTIAL GEAR OIL

TYRE REPAIR NAIL

INNER C.V. JOINT

VACUUM THERMOS FLASK(BLACK)

VACUUM THERMOS FLASK(PINK)

ENGINE PISTON

PISTON RING SET

CYLINDER LINER

ENGINE VALVES

FUEL LINE HOSE

CLUTCH OPERATING CYLINDER

CLUTCH MASTER CYLINDER

CLUTCH CYLINDER REPAIR KIT

SIDE ROD ASSY

PITMAN ARM

IDLER ARM

AIR SUSPENSION COMPRESSOR

PARKING SHOE

BRAKE DRUM

BRAKE CALIPER

DRIVE SHAFT BOOT KIT (TPEE)

DRIVE SHAFT BOOT KIT (SILICONE RUBBER)

STEERING BOOT (TPEE)

STEERING BOOT (SILICONE RUBBER)

FLAT JOINTS PIPE

Truck Wheel Hub Nut

Truck Wheel Hub Bolt

COTTER PINS

NYLON CABLE TIES

MASS AIR FLOW SENSOR CLEANER

DRIVESHAFT COUPLING

HYBRID WIPER BLADE

AUTO BULBS

TIRE SHINE

FLAT WIPER BLADE

SHOCK ABSORBER DUST COVER

GASKET EXHAUST PIPE

Felt bag

Memo book

DISPLAY STAND

Long pants autumn outfit

T-SHIRT

Summer Green T-shirt

Orange shirt

Orange Polo Half Sleeve

Summer short sleeves

White long sleeved shirt

White long sleeved shirt

T-SHIRT

Autumn long sleeved suit

Winter cotton clothing

White Short Sleeve

Black short sleeved shirt

Autumn long sleeves

Sealing tape

card case

Square lightbox

Rectangular lightbox

lighter

Tank oil machine

Car trunk rope hook

LOGO lamp

Dragging money tray

mug

Key Chain

wall calendar

Ceramic water cup

pen container

Japanese advertising pen

Purchase Order

towel

Black ashtray

New sealing tape

tape measure

flagpole

Oil brochure

Yellow sticker

Black sticker

Black sticker

Leaf board pad

glove

Brake disc disc drive

Stickers

poster

poster

poster

poster

poster

poster

poster

poster

poster

poster

poster

Leaflets

Brake disc sample

Ball head sample

Oil filter wrench kit

The brochure

product catalog

new book

tool

paper cup

Grey power bank

Black power bank

Material gifts

Picture Frame

tissue

poster

Power of Attorney

Refrigerant thermometer

Picture Frame

Leaflets

Stickers

glove

glove

glove

Advertising television

Half length sleeve

Half length sleeve

poster

poster

Orange triangle neutral pen

COMPANY FLAG

COMPANY FLAG

COMPANY FLAG

COMPANY FLAG

Air flow meter

Fuel pipe rack

Radium colored plastic bag

Steering joint connector

lead screw

nut

Tire pressure sensor

Engine Systems

Drivetrain Systems

Suspension & Steering

Brake Systems

Dust cover Series

Air Conditioning System

Filter Series

Exhaust Gas Systems

Fastening Series

Body parts

Electrical Parts

Automotive lighting

Tire Repair Supplies

Chemical Goods Series

Lubricants & Fluids Series

Service tools & Equipment

Others

GET A FREE CONSULTATION

Your Message to Us *

File *Max. File Size: 2 GB.